Matting principle of paint and types of common matting agents

In contemporary times, the coating industry is developing rapidly, during which the high glossy glossy coatings are loved by consumers for their bright and vivid color and other advantages, and have occupied the coating market for quite a long time. However, the reflection of high gloss glossy coatings is more serious after the film is formed, which gives people a blinding feeling. At the same time, it is harmful to human eyes. On the other hand consumers' aesthetic concepts are more and more inclined to leisure, fashion and personalization. These factors then lead to a sharp increase in the demand for low-gloss coatings with a soft appearance. Therefore, the question of how to produce coatings with matting properties has become a necessary consideration.

In contemporary times, the coating industry is developing rapidly, during which the high glossy glossy coatings are loved by consumers for their bright and vivid color and other advantages, and have occupied the coating market for quite a long time. However, the reflection of high gloss glossy coatings is more serious after the film is formed, which gives people a blinding feeling. At the same time, it is harmful to human eyes. On the other hand consumers' aesthetic concepts are more and more inclined to leisure, fashion and personalization. These factors then lead to a sharp increase in the demand for low-gloss coatings with a soft appearance. Therefore, the question of how to produce coatings with matting properties has become a necessary consideration.

It is believed that matting is the use of various means to destroy the smoothness of the coating film, increase the surface microscopic roughness of the coating film, and reduce the reflection of light from the surface of the coating film.

Matting methods can be roughly divided into: physical matting and chemical matting.

Physical matting: Adding matting agent to make the coating in the process of film formation, the surface produces unevenness, increasing the scattering of light and reducing reflection.

Chemical matting: The introduction of light-absorbing structures or groups, such as polypropylene grafting substances, into the coating to obtain low gloss.

In today's coatings industry, the method of adding matting agents is commonly used. The main types of matting agents are: metal soaps, waxes, functional fines.

Figure 1. Aluminum Stearate

Metal Soaps

Metal soap is a kind of matting agent commonly used in the early days, which is mainly some metal stearates, such as aluminum stearate, zinc stearate, calcium stearate, magnesium stearate and so on. Among them, aluminum stearate is the most used.

The matting principle of metal soap is based on the incompatibility between it and the coating ingredients, it is suspended in the coating with very fine particles, and when the film is formed, it is distributed on the surface of the coating film, so that the surface of the coating film produces microscopic roughness, and reduces the reflection of the light on the surface of the coating film to achieve the purpose of matting.

Wax

Wax is a kind of matting agent which is widely used earlier, and it belongs to organic suspension type matting agent. After the construction of the coating is completed, with the volatilization of the solvent, the wax in the coating film is precipitated and suspended in the surface of the coating film with fine crystals, forming a layer of roughness that scatters light and plays the role of matting. There are a variety of different paraffin wax products on the market. Wax products based on polyethylene, polypropylene and Brazilian waxes are most commonly used in coatings and inks.

Wax as a matting agent is characterized by its ease of use and can give the coating film a good feel and resistance to water, heat and humidity, and staining. However, the wax layer formed on the surface of the coating film will also prevent the evaporation of solvents and the penetration of oxygen, affecting the drying of the coating film and recoating. The future development trend is to synthesize polymer wax and silica and use it to get the best matting effect.

Figure 2. Polymer synthetic wax powder

Functional fine material

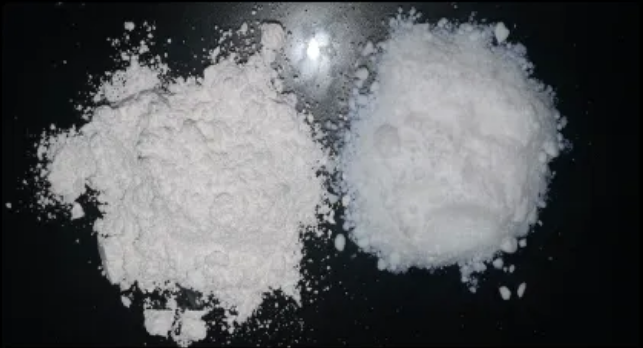

Such as talcum powder, diatomaceous earth, kaolin, fumed silica, etc. are special for matting agent functional fines, which belongs to the inorganic filler-type matting agent. When the coating film is drying, their tiny particles will form a micro-rough surface on the surface of the coating film, reducing the reflection of light to obtain the appearance of matting.

Figure 3. (Left: ultrafine talc, right: aerosilicate)

Ultrafine talc has similar physical and chemical properties with pyrogenic silica, and the oil absorption value is lower than that of pyrogenic silica, adding a relatively high proportion can reduce the use of a certain amount of pyrogenic silica, but also can promote a certain amount of abrasion and scratch resistance properties of the coating, and at the same time, give a matte effect;

For coating viscosity system can also play a good thickening and anti-sinking effect;

In industrial paints, anti-corrosion coatings and other formulation design, often choose to use the two synergistic way of adding to assist the final shape of the coating