What are the methods for surface modification of ceramic grade talc?

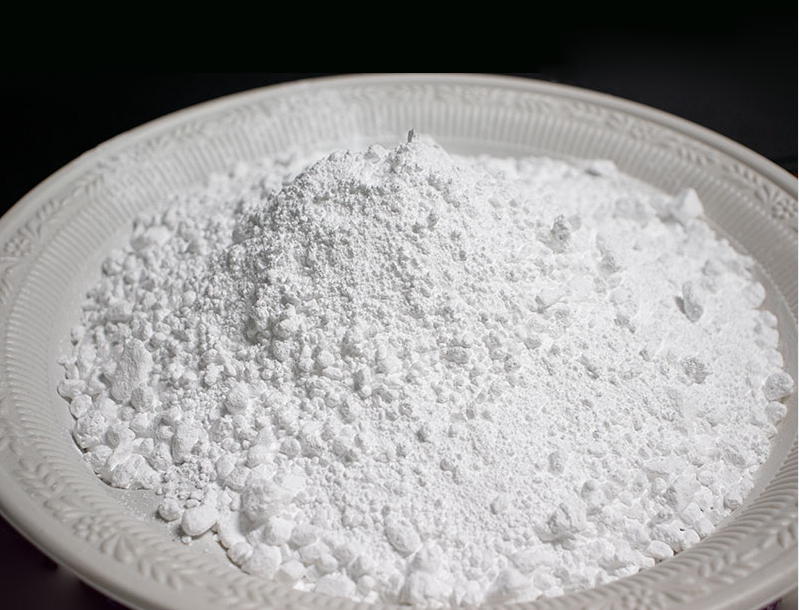

Ceramic grade talc and calcium carbonate are used for filling, the purpose of which is mainly to increase the dimensional stability (that is, shrinkage reduction), increase the stiffness of the material, increase the heat resistance of the material, and reduce the cost of the material in several aspects. Because of its high temperature does not change color, wrought whiteness enhancement, uniform density, good luster, smooth surface, etc., often used in the manufacture of high-frequency ceramics, radio ceramics, a variety of industrial ceramics, construction ceramics, ceramics for daily use and ceramic glaze and so on.

What are the methods of surface modification of ceramic grade talc?

Ceramic grade talc and calcium carbonate have the same distinction of particle size, the surface covering modification is to coat a layer of surfactant on the surface of talc particles to make it have new properties.

The process uses a surfactant or coupling agent to change the surface of the particles from hydrophilic to hydrophobic through chemical bonding or adsorption, thus improving the compatibility of the particles with the polymer. This is a widely used method.

Mechanochemical method: This method reduces the size of the particulate particles by crushing and friction, thereby increasing the adsorption force on the surface and thus reducing the absorption of other substances, thus simplifying the production process, lowering the cost of production, and improving the quality of the product.

Outer film layer modification method: A method of changing the surface characteristics of particles by uniformly coating a layer of polymer on the surface of microfine talc particles, i.e. local activation modification: By chemically modifying the particles, it combines with them on the surface of the particles and makes them have good compatibility with polymers, so as to realize the combination of the particles and the polymers.