Transparent filler applications

Previously mentioned in the soft, now different industries for the increasing demand for transparent inorganic filler, transparent inorganic filler filler modified plastics, coatings and other industries, in order to meet the physical and chemical properties of the decline in the case of a small amount, but also has a good light transmittance.

Common inorganic fillers such as common talc, calcium carbonate, etc., due to its refractive index and the vast majority of the resin difference is large, so after filling, for the finished product of the light transmittance has a greater impact, so the early transparent, light-transmitting plastics or coatings are less or no filler, resulting in a high overall cost, so manufacturers are also constantly looking for ways to reduce costs. With the development of inorganic filler industry, transparent filler gradually enter the market, many transparent filler on the market are called transparent powder, but each manufacturer's transparent powder may be different inorganic non-metallic mineral materials, such as: metamorphic powder, quartz powder, calcium sulfate, as well as special talc, calcium carbonate and so on. The differences in chemical composition and crystal structure lead to different transparency and performance in different material applications. The following briefly introduces the application of different transparent fillers in various industries.

1.Modified plastics:

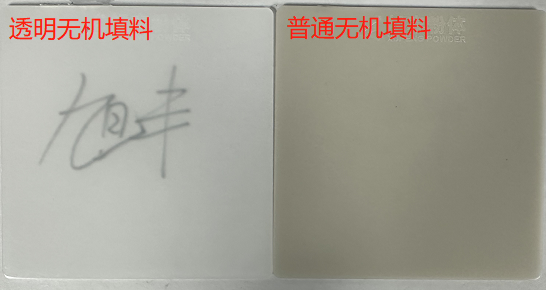

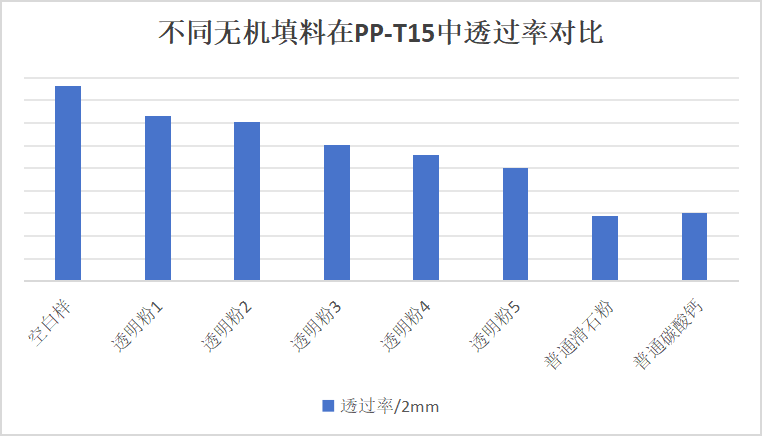

Comparison of transparent inorganic fillers and common fillers in PP-T20

In the modified plastics industry, there are many products with demand for apparent transparency, such as: lunch boxes, transparent shoe boxes, lampshade panels and so on. Traditional fillers, such as ordinary talcum powder, calcium carbonate for the material transmittance has a greater impact on the transparent inorganic fillers added relative to ordinary fillers, the transmittance rate has a substantial increase.

2. Shoe material industry:

TPR semi-transparent sole

With the development of shoe material industry, the material of shoe material industry has also undergone a radical change. In recent years, transparent or semi-transparent TPR outsole is very popular among consumers, but the price of TPR material is relatively high, and filling traditional filler will greatly reduce its transparency, affecting the aesthetic appearance, so the transparent inorganic filler has a wide range of applications in transparent or semi-transparent soles.

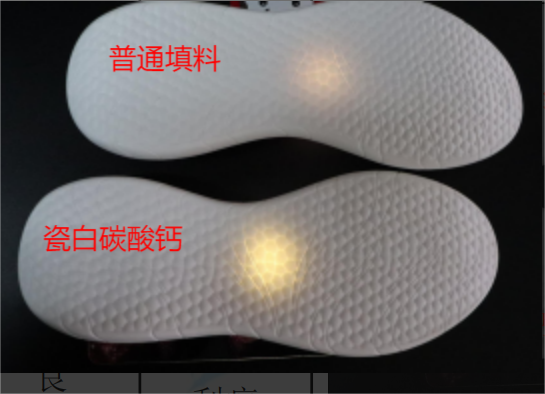

Imitation popcorn shoe material

In addition to the above transparent or semi-transparent TPR soles, imitation popcorn shoes also have a certain demand for light transmittance, this is due to the ETPU made of real popcorn soles process and the special nature of the material, the finished product has a certain degree of light transmittance, and by the EVA material made of imitation popcorn shoes, if filled with ordinary fillers, the light transmittance is insufficient. Therefore, in the production process of EVA imitation popcorn shoes, the ordinary filler can be changed to our porcelain white series of calcium carbonate, to improve the light transmittance, and improve the realistic effect of imitation popcorn shoes.

In addition to the above modified plastics, footwear industry, such as film materials, coatings and other industries also have a demand for transparent inorganic fillers, the subsequent article will give you transparent inorganic fillers in the rest of the industry applications!