The role of talc in automotive lightweighting

In recent years, the automobile industry mainly focuses on the theme of "light weight, energy saving, high speed, safety, comfort and low cost", of which light weight is the key. Comparison of the specific gravity of several materials commonly used in automobiles: A3 steel 7.6, brass 8.4, aluminum 2.7, while the specific gravity of general plastics is only 0.9-1.6, and the specific gravity of glass fiber reinforced composite materials is also within 2. Therefore, although plastic is not as strong as carbon fiber, metal and other materials, but plastic has the best lightweight effect, high specific strength, and excellent processability, is the preferred material for automotive lightweight. The use of plastics can reduce the weight of parts by about 40%, and the power, comfort and safety of automobiles can be improved.

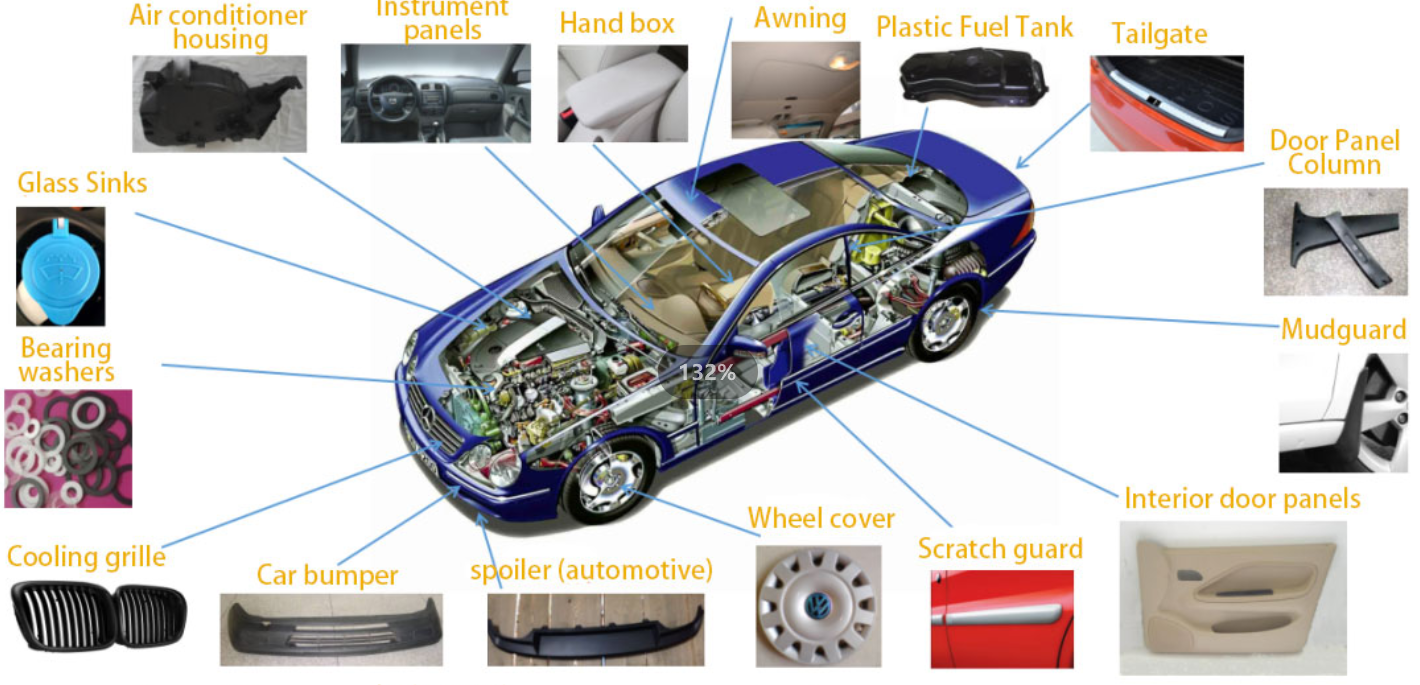

Polymer materials used in the automotive industry includes a wide range, such as PP, ABS and its alloys are mainly used for interior and exterior parts, PA materials are mainly used for power, chassis parts and structural components, PC, POM, etc. are mainly used for electronic and electrical parts and structural components, rubber is mainly used in automotive tires, hoses, drive belts, shock absorbing blocks, seals and so on. At present, the amount of domestic automotive plastics accounted for about 10% of the weight of the car, of which the largest varieties of PP, the other in order of PVC, PU, ABS, PE, PA and so on.

As an important filler component in modified PP, talc has excellent physical and chemical properties such as lubricity, anti-adhesion, flow-assisting, refractory, acid-resistant, insulating, high melting point, chemically inactive, good covering power, softness, good luster, strong adsorption. The addition of talc can change a variety of plastic properties, such as molding shrinkage, surface hardness, flexural modulus, tensile strength, impact strength, heat transformation temperature, molding process and product dimensional stability. So how to choose the right talc powder according to the needs of the formula is particularly important!