Selection and collocation of waterborne intermediate paint filler in automobile

Automobile coating has always been one of the major pillar industries of the coating industry, at the same time by the field of automobile coating on the "quality" control, emergence of cathode electrophoresis, electrostatic spinning cup and other construction methods, so many people in the industry believe that the field of automobile coating car coating represents the national paint industry technical level and development direction.

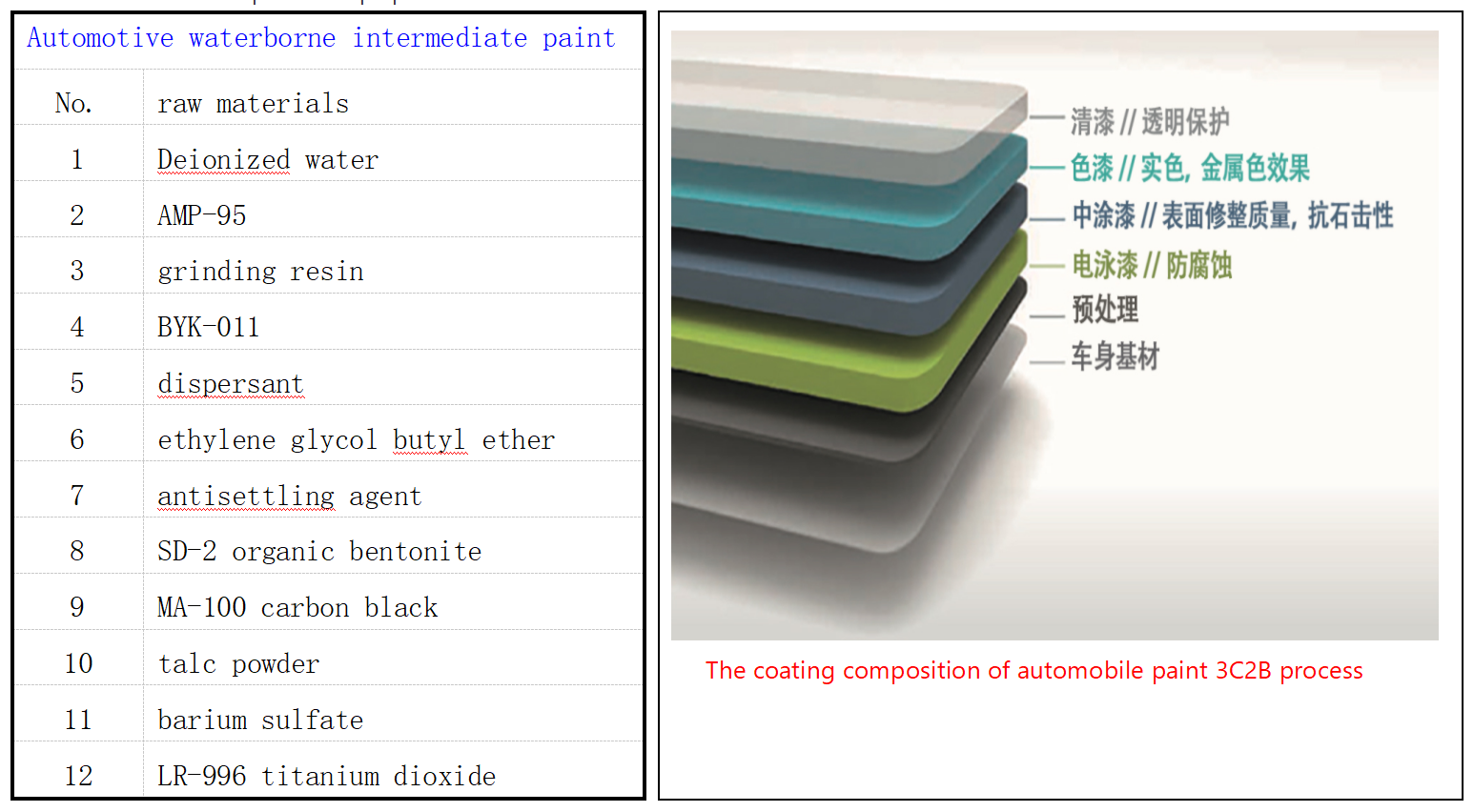

With the continuous improving and development of the raw materials of our country, automobile coatings are also gradually expanding from the application of cars to trucks, pickup trucks, motorcycles and other commercial vehicles and light industry. At the same time, due to environmental protection and the market high demand for commercial trucks, the commercial truck market gradually changed from solvent-based to water-based and high-solid products. In order to adapt to the production time of traditional solvent truck market, the product process of water-based 3C2B was developed, in which the middle coating kept the original drying process.

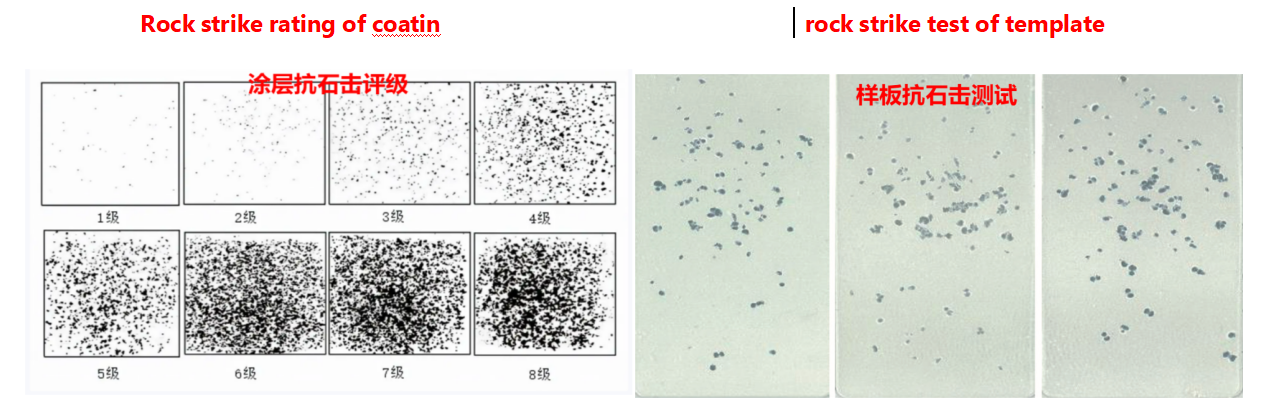

Medium coating can not only firmly adhere to the electrophoretic primer coating surface, but also easy to combine with the top coat coating, and give the overall coating more excellent rock impact resistance, impact resistance and other effects; With filling, can effectively eliminate the pits, lines and sandpaper marks brought by primer, putty, etc., so that the spray paint and varnish to get more smooth and plump coating, improve the brightness and fullness of the whole film; At the same time, it can effectively reduce the pulverization effect of UV on the electrophoretic primer coating, optimize the overall weatherability of the coating and improve the service life of the coating.

Automotive coating with the role of the primer layer is different, do not need to play the role of rust and corrosion prevention, makeup filler generally to titanium dioxide, carbon black, talc and barium sulfate, etc.; Talc powder has excellent dryness and grinding powder, at the same time, its excellent suspension and thickening properties can also play a synergic anti-sedimentation effect with anti-sedimentation agent, but its oil absorption value is large, high extinction, there is a certain amount of limitation. Barium sulfate has excellent acid and alkaline resistance, and its low oil absorption value has little impact on coating luster, and can play a certain synergistic UV resistance effect. However, barium sulfate has a large proportion and is easy to precipitate, so auxiliary bentonite or other rheological additives need to be used together.

That is, talc powder and barium sulfate are generally used in waterborne intermediate paint, which can effectively synthesize the advantages of the use of the two fillers, play the role of acid and alkali resistance, improve the surface dryness and grinding property, and at the same time make up for their own defects. At the same time, because the surface of the medium coating is protected by color paint and varnish, some middle and low-end customers can choose to use the combination of natural barium and talc powder.

The following is the common waterborne intermediate paint raw material formula, the formula uses resin grinding process, can better cover the coating filler, and improve the stability of the finished product and mechanical properties; In the color paste raw materials after dispersion, grinding to formulate fineness and filtration process, according to the sequence and dispersion process to add the main resin, amino resin, solvent, additives, etc., can form a complete water-based coating of the original paint formula. A certain amount of water is added to dilute the product to the specified viscosity for spraying, and the plate is made according to the baking process. After baking and cooling, the color paint and varnish are sprayed according to the requirements, and the corresponding automobile water-borne 3C2B sample can be prepared.