Application of powder in adhesive

Adhesives, a pivotal cornerstone of industry, are used in a wide range of key areas such as construction, automotive manufacturing, electronics and packaging, demonstrating their irreplaceable breadth and importance. In this series of applications, powder as the key additive of adhesives, like the magic powder in the hands of a magician, plays a pivotal role, adding infinite possibilities for the performance of adhesives. The purpose of this paper is to analyze the multiple applications of powders in adhesives and their core values.

The application of powders in the world of adhesives is as colorful as a kaleidoscope, in which inorganic powders such as silica micropowder, talc, heavy calcium carbonate and zinc oxide have become indispensable jewels in the formulation of adhesives by virtue of their unique physicochemical properties. They not only add volume to the adhesive, effectively reducing production costs, but also like magic to give the adhesive a number of functional qualities, such as improving the modulus of elasticity and impact toughness, enhanced thermal conductivity and heat resistance, as well as a significant reduction in the coefficient of linear expansion and shrinkage, etc., so that the performance of the adhesive jumped to a new level.

The surface properties of powders, such as hydrophilicity, hydrophobicity and charge, act as character labels, profoundly influencing their interaction patterns with other substances, and thus subtly regulating the overall performance of the adhesive. The chemical composition of the powder, like its inherent genes, determines its reaction potential with other components, providing a scientific basis for selecting the most suitable adhesive filler.

Faced with a wide range of powder options, how to recognize the pearl? The key lies in accurate matching. We need to start from the specific needs of the adhesive system and the desired performance, carefully selected to meet the performance requirements, but also harmonious coexistence with the system, easy to disperse and does not cause adverse reactions of the powder. At the same time, safety, economy, accessibility and ease of processing and other comprehensive considerations are also indispensable to ensure that the selected powder is not only excellent performance, but also low cost, wide range of sources and other practical advantages.

Calcium carbonate, for example, is a common filler powder that shines in the field of adhesives because of its low price, fine uniformity and excellent whiteness. Especially in the emulsion-type adhesive for wood, calcium carbonate can not only effectively adjust the viscosity, but also significantly improve the hardness and bonding strength, providing a solid support for the optimization of adhesive performance.

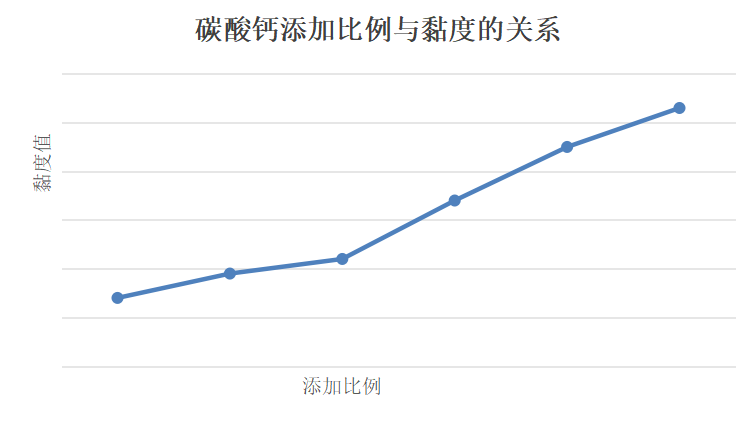

I. Relationship between the addition ratio of calcium carbonate and adhesive viscosity

The test results show that with the increase of calcium carbonate addition, the viscosity value first increases slowly, and then rises rapidly. Choosing the right proportion can adjust the viscosity and flow state of the adhesive, so that it can reach the best construction viscosity.

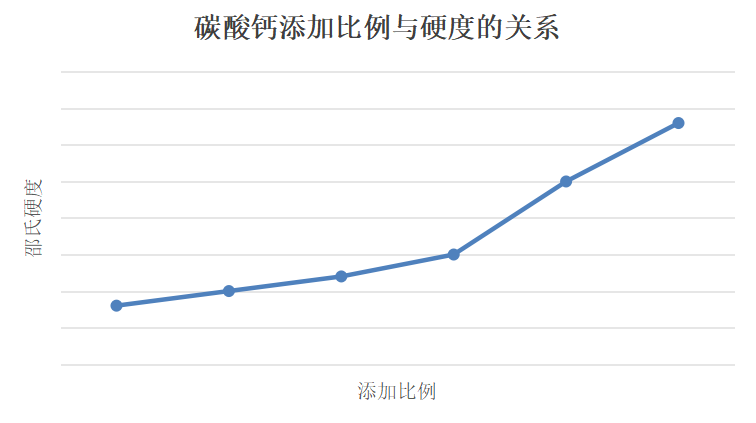

Second, the relationship between the addition ratio of calcium carbonate and adhesive hardness

After testing, with the increase of calcium carbonate additive amount, the overall Shore hardness of the adhesive is not obvious, after reaching a certain additive amount began to rise. Therefore, choosing the right proportion can make the adhesive have better hardness and performance.

Powder in the adhesive in a wide range of applications, they can not only improve the performance of the adhesive, but also can reduce costs, give special features. With the continuous progress of technology and application, the role of powder in adhesives will be more and more important, providing more possibilities and opportunities for the development and application of adhesives.

Our main talcum powder, calcium carbonate and other types of inorganic powders and modified powders, for more application information or samples, please scan the following micro-signal or call us directly, Xufeng Powder wholeheartedly for your service!