Application of modified calcium carbonate in adhesive

Adhesive is generally made of bonding material (matrix resin), curing agent, toughening agent, diluent and filler, etc. It is widely used in packaging, electronic and electrical appliances, building materials, automobiles and transportation, machinery manufacturing, new energy, medical health, aerospace and other fields.

At present, calcium carbonate can be used in a variety of adhesive/sealing material (resin) systems, such as: polyurethane, polysulfide, polysiloxane, modified polysiloxane, polybutene, urea formaldehyde resin, phenolic resin, epoxy resin, etc. However, the inorganic powder filler and the matrix surface or interface properties are different, the compatibility is poor, it is difficult to disperse evenly in the matrix; Secondly, the high oil absorption value limits the application viscosity of the product, so the addition ratio is low; There are some fillers with high relative density and poor stability, which are easy to precipitate in the system; Improper selection of powder has a very large impact on rubber products, and the bottom filling glue with poor quality is easy to cause trouble during use, such as poor dispersion, poor impact resistance leading to fragile, and too long curing time affecting work efficiency.

The application of calcium carbonate in adhesives mainly focuses on three aspects:

1. Mixing of filler and colloid;

2. The effect of filler on thixotropic performance;

3. The enhancement of sealant;

The main factors affecting the blending performance of nano-calcium carbonate in sealant are: particle size, crystal shape, oil absorption value, specific surface area, pH value, sieve residue, moisture and so on. Among them, the main factors affecting the thixotropy of colloid are: particle shape, oil absorption value, surface modification and pH value; The main factors affecting the enhancement are particle size and dispersion. So choosing the right filler is crucial.

Adding fillers to various types of adhesives to optimize the formula has been a common and effective method, which can not only increase the volume of adhesives by adding fillers, thereby reducing costs; At the same time, the addition of fillers can also improve the poor heat resistance of the adhesive itself, high curing shrinkage, low hardness and unstable viscosity and other problems, which has positive significance for expanding the use of adhesives. In addition to the calcium carbonate mentioned in this paper, the common fillers are montmorillonite, kaolin, silica, titanium dioxide, silicon carbide and so on.

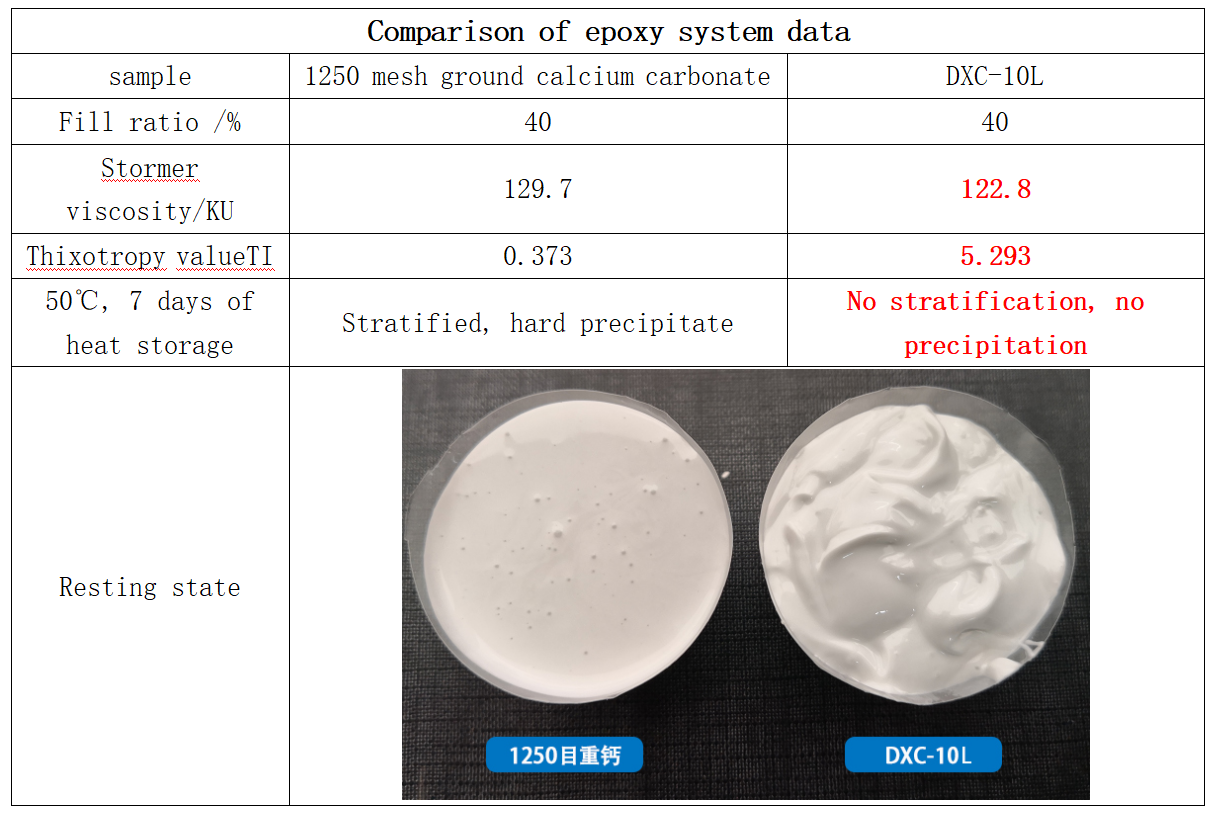

The low oil absorption activated calcium developed by our company for adhesive problems has better oil phase compatibility, abrasiveness, dispersion, anti-settlement, and has strong thixotropy, low system viscosity under high stirring state, reducing processing energy consumption and improving production efficiency; High system viscosity in static or low stirring state, greatly improving the storage stability of the product.

Table 1: Effect of low oil absorption active calcium in epoxy adhesives

More product application information or sample needs, welcome to inquire, Xufeng powder wholeheartedly at your service!