Analysis and evaluation method of surface modification effect of powder (Part 1)

In recent years, surface modification is one of the most active and fastest developing technologies in the field of non-metallic mineral powder processing, and it is also an important means to improve its application performance, expand the market and consumption. Therefore, it has received much attention from the non-metallic mineral powder industry and downstream application industries.

In the production process, it is very important to evaluate the surface modification effect and adjust the modifier, process and equipment parameters in time according to the modification effect. At present, the characterization and evaluation methods of surface modification effect of inorganic nonmetallic mineral powders such as calcium carbonate, talc powder, silica powder, kaolin, barite powder, wollastonite powder can be divided into direct method and indirect method.

The direct method is to determine the physical and chemical properties of the powder after surface modification or surface treatment; The indirect method is to determine the application performance of the powder after surface modification in the application field.

Characterization evaluation method | Item |

Direct method | Activation index,oil absorption value, particle size distribution and microscopic morphology,contact Angle,surface energy,electrical properties,optics and wave absorption properties. |

Indirect method | Fill in the dispersion of polymer composite materials, mechanical properties, electrical properties, coatings and coating materials, optical, electrical, thermal, chemical properties, etc. |

This paper first introduces several direct methods of powder characterization evaluation and related cases for your reference, we can choose one or more characterization evaluation methods according to their actual needs to evaluate the modified powder.

1. Activation index

For the surface modification to improve the compatibility of inorganic fillers or pigments with polymers or surface hydrophobicity, the "activation index" can be used to detect or characterize the effect of surface modification.

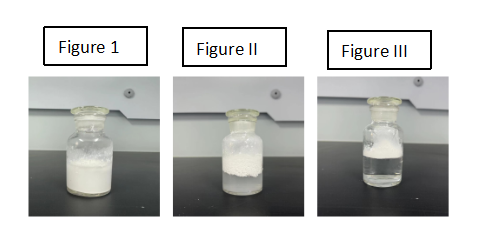

The activation index refers to the non-infiltration of water to the inorganic pigment filler, that is, the hydrophobicity of the inorganic pigment filler. Figure 1 shows the effect of unmodified talc in water, completely soaked by water; Figure 2 shows the effect of ordinary modified talc powder in water. Part of the powder is soaked by water and sinks to the bottom. Figure 3 shows the effect of our super hydrophobic series talc powder in water, which can achieve a completely hydrophobic effect, and the bottom water is almost completely clarified.

2. Oil absorption value

Oil absorption value, also known as resin adsorption, represents an index of the amount of resin absorption of the filler. In application, most fillers use the oil absorption value to predict their resin demand, so as to deduce the maximum proportion of fillers added in the formulation system. The oil absorption value is usually expressed in the volume of DOP oil required for 100g filler (some coating customers use the old national standard castor oil test), that is, the minimum amount of oil per 100g filler when it reaches full wetting.

Surface modification is an important means to reduce the oil absorption value of the filler, the smaller the oil absorption value, the less the resin adsorption capacity, the higher the filling ratio, the following is the oil absorption value of several calcium carbonate comparison.

sample | 1250 mesh heavy calcium | Ordinary active calcium carbonate | Our low oil absorption activated calcium |

Oil absorption value, ml/100g | 30±1 | 18±1 | 11±1 |

3. Contact Angle (infiltration Angle)

The main significance of the contact Angle is to understand the nature of the interaction between the surface of the object and the liquid or gas, and to evaluate the wettability and surface properties of the material.

By measuring the contact Angle between the droplet and the solid surface, the development of the liquid on the solid surface can be understood. The smaller contact Angle means that the liquid is more easily spread on the surface, indicating that the material has good wettability. The larger contact Angle indicates that the material has a strong non-wettability to the liquid.

Surface energy is an index describing the adsorption capacity of solid surface, which plays an important role in the expandability of liquid on solid surface. By measuring the contact angles of different liquids on a solid surface, the surface energy of a solid can be calculated and thus its interaction with different types of liquids can be evaluated.