Amphiphilic activated calcium in polypropylene

SQC series activated calcium carbonate is made from ordinary calcium carbonate, added with compound dispersing modifier, and surface coated by surface treatment equipment. At the beginning of the development, the main purpose is to improve the calcium carbonate in the coating industry production and use process, fineness, difficult to grind, dispersed viscosity is high, easy to precipitate and so on, so the development of the SQC series of activated calcium carbonate, which has hydrophilic, lipophilic amphiphilic characteristics, named amphiphilic type activated calcium.

In the process of application promotion, it is found that SQC series of activated calcium carbonate is not only suitable for paint and coating industry, but also can be used in modified plastics, rubber and so on to do filler and modifier. Take the application of amphiphilic activated calcium in modified polypropylene as an example, it has more excellent performance compared with ordinary heavy calcium carbonate.

Application of amphiphilic activated calcium in modified PP:

Note: The data in this report is real and reliable, and the data is for reference only.

Advantage analysis

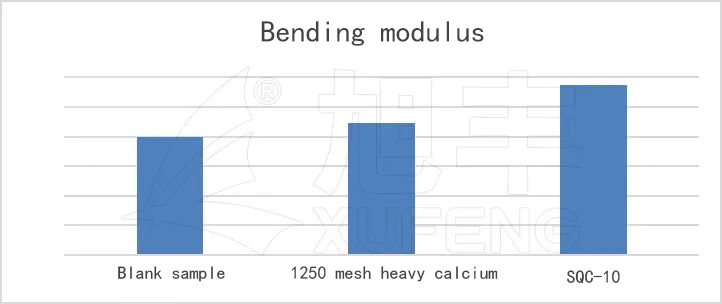

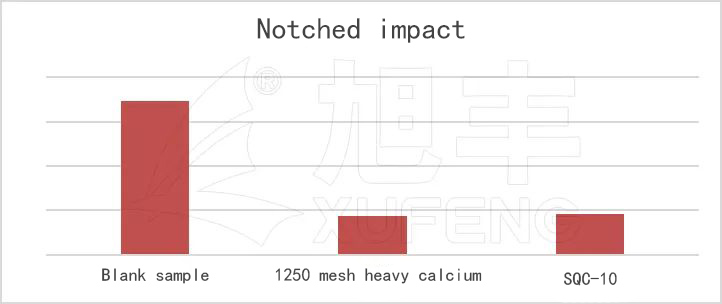

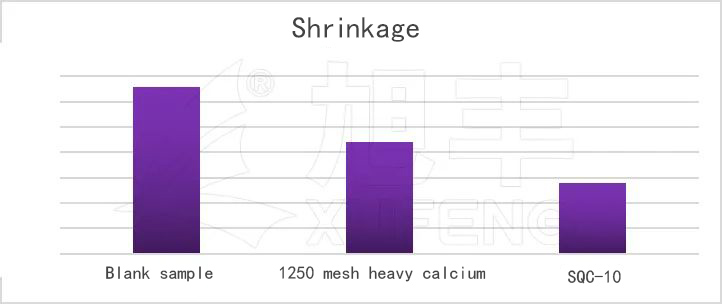

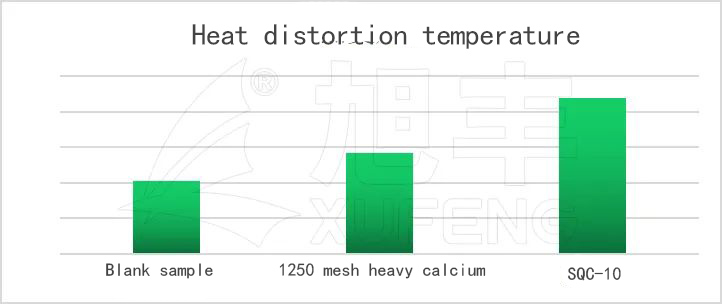

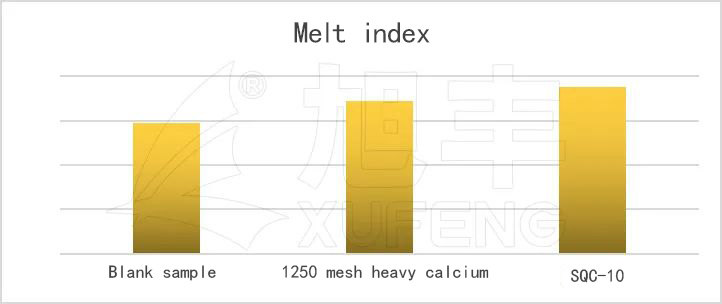

Amphiphilic activated calcium SQC-10 is more compatible with PP resin, and the overall mechanical properties have been improved to different extents, among which the flexural modulus has been increased by 25% to 30%, and the notched impact, heat distortion temperature and melting index have been improved to a small extent; and the shrinkage has been reduced, and the dimensional stability has been improved.