Transparent filler and its application

In recent years, the price of raw materials has risen sharply, the market competition is fierce, and the consumer demand for quality is constantly improving, manufacturers only try, explore and research, product upgrading while strict cost control, in order to have a stronger core competitiveness.

The most direct way to reduce the cost of plastics and coatings industry is to fill modification, but with the increase of the proportion of filler added, the transparency of composite resin decreases significantly, for has transparency or light transmittivity requirement products, such as wood paint, film, hose, etc., conventional filler can not meet the requirements, so the transparent filler is developed. This time around the advantages and disadvantages of several common transparent fillers to share with you, for your reference!

Transparent powder1 | Transparent powder2 | Transparent powder3 | Transparent powder4 | Transparent powder5 | |

refractive index | 1.54 | 1.48 | 1.57-1.61 | 1.53 | 1.55-1.57 |

transparency | good | good | better | better | better |

Mohs hardness | 6-7 | 1.5-2 | 1.5-2 | 7-7.5 | 1-1.5 |

sanding | difficult | medium | medium | difficult | easy |

density | 2.3 | 2.68 | 2.32 | 2.57 | 2.7-2.8 |

anti-sinking | better | poor | better | better | good |

compatibility | better | poor(easy precipitation) | better | better | better |

leveling and penetration | poor | poor | poor | good | better |

Theoretically, when the refractive index of the filler is similar to that of the matrix resin, it has little effect on the transparency of the composite resin, namely the transmittance. However, if there is a significant difference, it will obviously affect the transmittance of the composite resin. For example, the refractive index of alkyd resin is 1.4 (the refractive index of common plastic is about 1.5), and the refractive index of several transparent fillers is close to the refractive index of resin, so the transparency is better; And rutile titanium dioxide refractive index 2.6-2.9, the difference is large, so the transparency is poor.

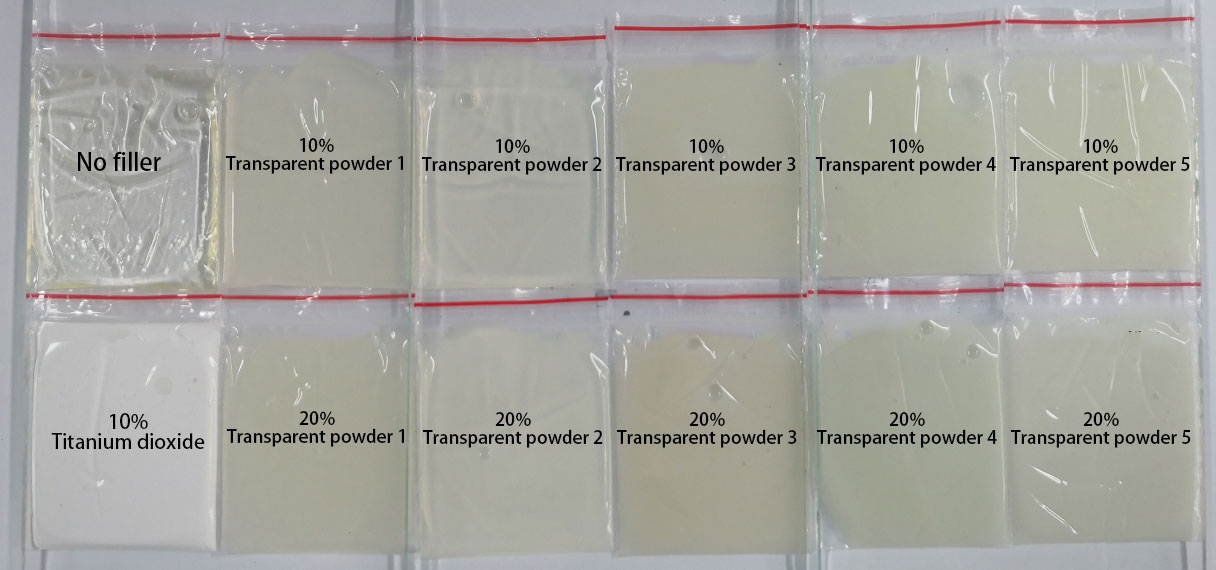

Figure 1 State of container with alkyd resin filled with 10% and 20% different transparent fillers

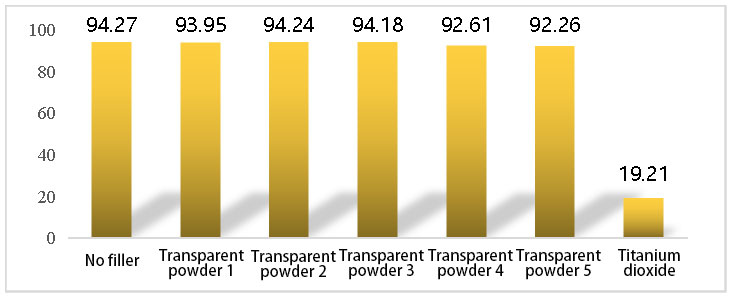

Then compare the light transmittance of these different transparent fillers, see Figure 2 and Figure 3 for details.

Figure 2 Comparison of transmittance of alkyd resin filled with 20%

Figure 3 Comparison of transmittance of alkyd resin filled with 20%

Note: Transparent powder 1, transparent powder 2 belong to the blue phase, the transparency of the picture under the yellow light is slightly worse than transparent powder 3, transparent powder 4, transparent powder 5 such yellow phase fillers.

It can be seen from Figure 1 that the transparency of transparent powder 1 and transparent powder 2 in the container state is higher than that of other transparent powders. But since transparent powder 1 and transparent powder 2 belong to the blue phase, the transparency of Figure 3 shows poor transparency under yellow light due to the camera. Therefore, customers in different industries can choose different types of transparent filler according to their own product needs, especially should pay attention to the selected transparent filler hue, refractive index, processability and other parameters.