Ultrafine functional calcium carbonate solves PBT common problems

Polypentoxalolated glycol (PBT) has excellent comprehensive properties, such as high crystallizing, rapid molding, weather resistance, low coefficient of friction, high temperature of thermal deformation, good electrical properties, excellent mechanical properties, fatigue resistance, ultrasonic welding and so on. However, its gap impact strength is low, the molding shrinkage is large, the hydrolysis resistance is poor, it is susceptible to halogenation erosion, after the glass fiber is enhanced, due to the inconsistent product, horizontal shrinkage rate is not consistent and easy to make the product warping。

This paper expounds the causes and solutions of common problems in PBT modification, and introduces a special inorganic non-metallic mineral product that can simultaneously improve pbT gap impact strength, poor fluidity, slow crystallization rate, surface floating fiber, warping and other problems - ultrafine functional calcium carbonate (hereinafter referred to as functional calcium).

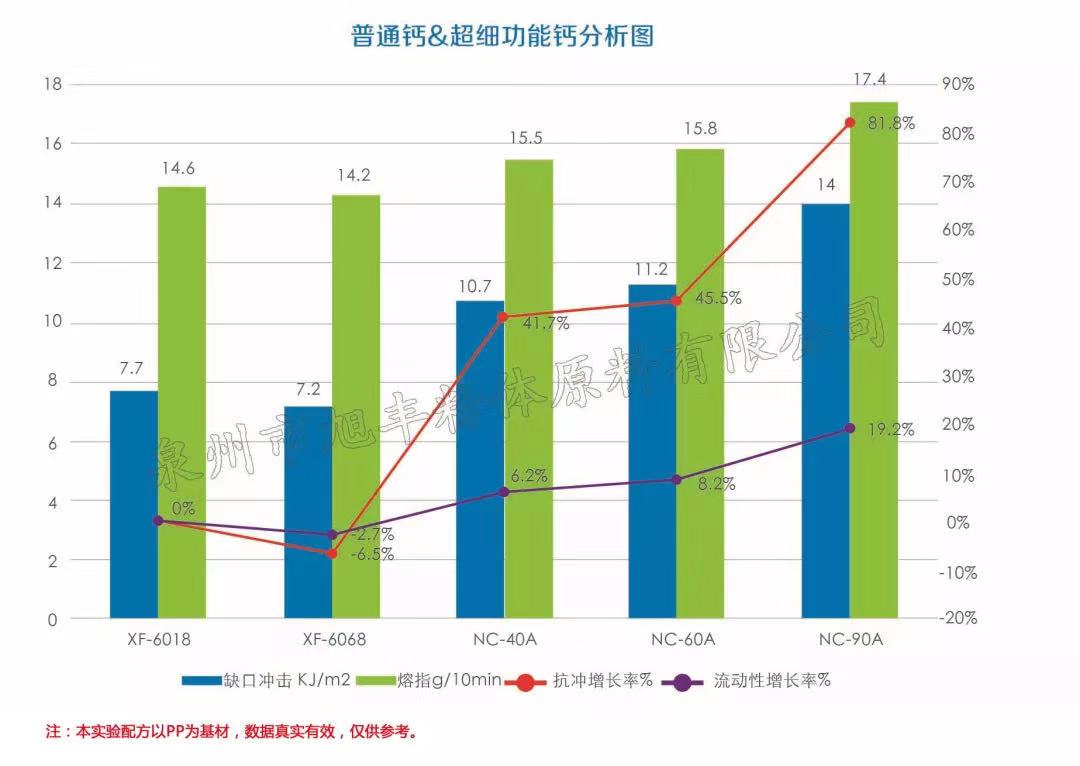

General Calcium and Ultrafine Function Calcium Analysis Chart

Division I research and development and production of functional calcium products are high anti-flush, high mobility of functional inorganic mineral powder, the series of products by special processing process, will be selected calcium carbonate ore grinding processinto into sub-nano-scale ultrafine powder, and then after surface treatment. The product NC-90A in improving the PBT gap impact strength is low, poor mobility at the same time, because of its ultrafine powder content of less than 2 m up to 85%, in the PBT crystallization process can also play an inorganic nuclear effect. In addition, the addition of functional calcium, the use of functional calcium spherical structure symmetry to reduce the differential sligo caused by the orientation of fiberglass, thereby improving the warping problem of PBT/GF composite materials. Inorganic mineral materials added to improve PBT/GF composite surface "floating fiber"

Gap sensitivity

Cause: The benzene ring and ester base in the PBT molecule form a large conjugate system, reducing the softness of the molecular chain, increasing the molecular rigidity, and the presence of polar ester base, niobium base so that the inter-molecular force increases, the molecular rigidity is further enhanced, thus toughness is very poor.

Solution:

A. Polymeric modification: polymerization modification is the introduction of new flexible chain segments in PBT molecules in the polymerization process by means of co-concentration, grafting, inlay, cross-linking and so on, so that it has good toughness;

B. Mixed modification: Comixed modification is to mix or compound the modifier or high impact strength material with PBT, so that it is distributed as a dispersive phase in the PBT substrate, using the partial compatibility of the two components or the appropriate interface bonding effect, to improve the gap impact performance of PBT.

PBT thin wall products need higher liquidity

Thin-walled electronic components in the electronic appliances, automotive electronics industry applications, components thinner is a trend, which requires the material needs higher mobility, in order to the smallest possible corresponding pouring equipment filling pressure or die force to achieve the filling of the mold. The use of low-viscosity thermoplastic polyester compositions can also often achieve shorter cycles. In addition, good fluidity is important for, for example, highly filled thermoplastic polyester combinations of glass fibers and/or minerals with a mass score of more than 40%.

Solution:

A. Select ingress PBT with low molecular weight, but the reduction of molecular mass will affect mechanical properties;

B. PBT mobility can be improved with the help of flow promoters such as stearate or lignite, but these low molecular mass esters can ooze during product processing and use;

C. For PBT materials that require emenantness, the addition of toughening agents (e.g. POE) will certainly lead to a decrease in liquidity, and therefore require the selection of toughening agents with less impact on liquidity;

D. Adding similar low-molecular polyesterwithe with a specific structure, such as CBT, CBT is a functional resin with large ring oligopolyester structure, with PBT has good compatibility, very little addition, you can greatly improve the liquidity of the resin, with little impact on mechanical properties;

E. Adding nanomaterials, ideally dispersed nanomaterials in PBT plays a similar role to internal lubrication, can improve the mobility of PBT, but the dispersion of nanofillers is a major difficulty in the process of mixing.

Glass fiber-enhanced PBT material easy to warp

Cause: Warping is the result of uneven shrinkage of material. The orientation and crystallization of components in the material, the use of inappropriate process conditions when injection molding, the shape and position of the gate when the mold is designed, the thick and uneven wall of the product design will cause the warping of the product. The warping of PBT/GF composite material is mainly the orientation of the glass fiber in the flow direction to limit the contraction of the resin, the induced crystallization around the glass fiber strengthens this effect, making the vertical (flow direction) contraction of the product is less than the horizontal (vertical direction of the flow direction), this uneven contraction leads to the warping of PBT/GF composite materials.

Solution:

A. Adding minerals to reduce the orientation of the glass fiber by using the shape symmetry of the mineral fillers;

B. Adding amorphous materials, reducing the crystallisity of PBT, reducing uneven shrinkage due to crystallization, such as adding ASA or AS, but they are poorly compatible with PBT and need to be added with appropriate compatibility agents;

C. Adjusting the injection molding process, such as appropriately raising the mold temperature, appropriately increasing the injection cycle

Glass fiber enhanced PBT surface float problem

Cause: PBT and glass fiber compatibility is very poor, resulting in the two can not effectively bond together, PBT and glass fiber viscosity is very different, resulting in the two in the flow process to form a separation trend, when the separation effect is greater than the adhesion will occur, glass fiber floating outward layer and leakage, shear force, will lead to local viscosity differences, And will destroy the glass fiber surface interface layer, melt viscosity is smaller, the interface layer is damaged, the viscosity of the fiberglass is also smaller, when the viscosity is small to a certain extent, the fiberglass will be freed from the shackles of the PBT resin substrate, gradually accumulated to the surface and exposed; The glass fiber, which is light-weight condensing, is frozen instantaneously, and if it is not fully surrounded by the melt in time, it will be exposed and form a "floating fiber".

Solution:

A. Add compatibility agents, dispersants and lubricants to improve the floating fiber problem. Such as the use of special surface treatment glass fiber, or add compatibility agent (e.g. SOG, a PBT modified compatibility agent), through the "bridge" role, increase the polysaccis of PBT and fiberglass;

B. Optimizing the molding process to improve the floating fiber problem. Higher injection molding temperature and mold temperature, large injection pressure and back pressure, faster injection speed, lower screw speed, can improve the floating fiber problem to a certain extent